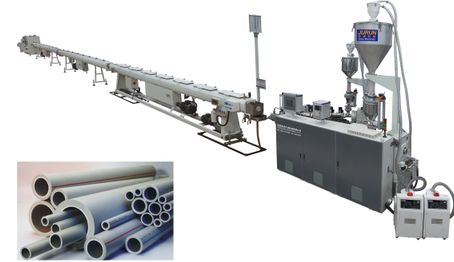

Plastic pipe production line is a kind of plastic machinery, plastic pipe sheet production lines are: PVC pipe production line, PP sheet production line, PE sheet production line. The following describes the lower level of three rolls of CO extrusion pipe production line and the level of three rolls of sheet machine production line units.

1 、 horizontal three roll double machine co extrusion pipe production line:

The unit is composed of main engine, screen changer, mould, three layer distributor, tablet press, conveyor, traction machine, cutting machine or coiling machine;

The reduction box is made of cast steel, the gears are made of alloy steel and treated by grinding. All lubrication points in the box are forced lubrication, and the lubricating oil is equipped with an efficient water cooling system.

The screw material is made of 38CrMOA1A high quality nitriding steel, and the alloy is sprayed by nitriding.

The cylinder material is made of 38CrMOA1A high quality nitriding steel, and the alloy is sprayed by nitriding.

Machinable raw materials are: PP, PE, PS and so on

Hierarchical structure: AB, ABA.

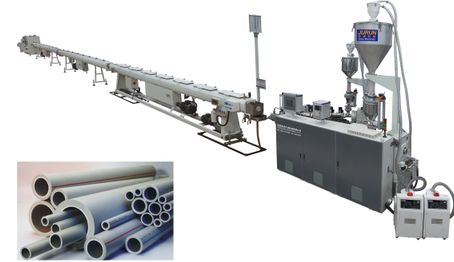

2 ��、 horizontal three roll single machine sheet machine production line:

The production line of plastic pipe is mainly composed of main machine, screen changer, mould, tablet press, conveyor, tractor, cutting machine, stacker or winding machine;

The reduction box is made of cast steel, the gears are made of alloy steel and treated by grinding. All lubrication points in the box are forced lubrication, and the lubricating oil is equipped with an efficient water cooling system.

The screw material is made of 38CrMOA1A high quality nitriding steel, and the alloy is sprayed by nitriding.

The cylinder material is made of 38CrMOA1A high quality nitriding steel, and the alloy is sprayed by nitriding.

Machinable raw materials are: PP, PE, PVC, PS, ABS and so on;